Request Publication

Steam reforming of hydrocarbon fuels

Catalysis Today

Vol. 77, Issues 1-2

1 Dec. 2002, pps 51-64

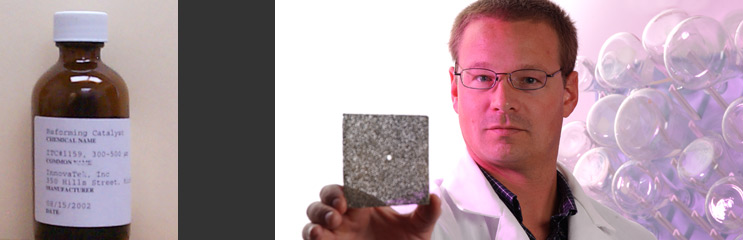

InnovaTek has developed proprietary catalyst formulas for fuel processing. The H2Tek® catalysts may be used for steam reforming, partial oxidation, and autothermal reforming of hydrocarbon fuels to produce hydrogen. Low temperature pre-reforming, water-gas shift, and high temperature reforming catalysts have been developed. The catalysts have been tested with a range of liquid and gaseous fuels with excellent results. Fuels that may be converted to hydrogen using these catalysts include:

- Natural gas

- Propane gas and LPG

- Gasoline

- Diesel

- Jet fuel

- Bio-Kerosene

- Ethanol

- Biodiesel

- Vegetable oil

The catalysts have been specifically developed for very high selectivity and reactivity in InnovaTek’s proprietary micro-channel reactors. Extremely high gas space velocities of 100,000 to 200,000 per hour are possible. Highly reactive catalysts such as these result in lower system costs because more fuel is converted for a specific catalyst volume compared to conventional catalysts. InnovaTek’s catalysts are also tolerant to some levels of sulfur in the fuel. The pre-reforming catalyst adsorbs sulfur and removes it from the process stream.